Door hardware refers to any item required for door functionality and aesthetics aside from the door, frame, and trim. ‘Rough Hardware’ consists of screws, bolts, anchors, nails, and miscellaneous fasteners. ‘Finish’ hardware is exposed to view and promotes and ease of operation. Hardware can be recessed or surface mounted.

If not laid out in detail on a projects door schedule to be priced during the bidding process, it’s common for contractors to include an allowance in their bid for the door hardware to be chosen by the project owner at a later date. Hardware can come in a number of finishes: stainless steel, brass, bronze, copper are quite common. Below is a list of the available hardware finish types labeled by both United States number and Builders Hardware Manufacturers Association:

| BHMA Code | US # | Finish |

| 600 | USP | Steel Primed for Painting |

| 603 | US2G | Zinc Plated Steel |

| 605 | US3 | Bright Brass, Clear Coated |

| 606 | US4 | Satin Brass, Clear Coated |

| 611 | US9 | Bright Bronze, Clear Coated |

| 612 | US10 | Satin Bronze, Clear Coated |

| 613 | US10B | Oxidized Satin Bronze, oil rubbed |

| 618 | US14 | Bright Nickel Plated, Clear Coated Brass |

| 619 | US15 | Satin Nickle Plated, Clear Coated Brass |

| 622 | US19 | Flat Black coated brass or bronze |

| 623 | US20 | Light Oxidized bright bronze |

| 624 | US20A | Dark Oxidized Statuary Bronze |

| 625 | US26 | Bright Chromium Plated brass or bronze |

| 626 | US26D | Satin Chromium plated brass or bronze |

| 628 | US28 | Satin Aluminum, Clear anodized |

| 629 | US32 | Bright Stainless steel |

| 630 | US32D | Satin Stainless Steel |

| 684 | Black Chrome, Bright brass or bronze | |

| 685 | Black Chrome, satin brass or bronze |

Different types of hardware and their functions are as follows:

Locks

Deadbolt – Primary types are single, double, and lockable thumb turn. Deadbolts are most commonly installed on exterior doors. SIngle cylinder deadbolts are the most commonly used in residential settings. A key cylinder is utilized on the outside and a thumb turner (or rosary) is used on the inside for open/closure. To avoid vulnerability to burglary in dooors with breakable window panes, a double key cylinder or hybrid lockable thumb turn may be used. Typically mounted +/- 60″ from floor.

Knob Locks – Used alot in residential exterior doors, and in tandem with deadbolts. Unfortunately the cylinder lock is typically inside the knob making it easy to break the knob and still open the door, hence the frequent coupling with deadbolts. Handedness and backset are options with knob locks.

Lever Handle Locks – Commonly used for interior doors in commercial construction. Simpler to open than knob locks and are popular with ADA design and usage. Handedness is often interchangable. Typically mounted +/- 45″ from floor.

Rim/Mortice Locks – Used alot in commercial construction, glass entry doors, apartment doors, etc they are machined or mortised into the door itself and typically flush. Typically mounted +/- 40″ from floor.

Interchangable Core Cylinder Locks – Core can be swapped out easily allowing for frequent rekeying if need be.

Jimmy Proof Lock – Surface mounted deadbolt mounted on the interior essentially eliminating lock access whatsoever from the outside. Popular in apartment complexes as a second line of defense.

Latches – Latches are used often in tandem with locksets to temporarily hold a door closed and/or add an additional amount of security. They are also utilized frequently on outbuildings (barns, sheds, cold storage buildings, etc). A Latchbolt is a very commonly used latch type where a long cylindrical piece slides in and out of the latching mechanism.

A Deadlatch is similar to a Latchbolt but has a guardbolt used to eliminate the possibility of Jimmy-ing the latch out from the opposite side of the door.

A ‘nightlatch’ or ‘springbolt lock’ is similar to a jimmy-proof lock being flush mounted but has a concealed throwbolt.

A ‘SLam Latch’ is spring activated and engages when a door is shut, common in rugged construction applications. There are several other old-fashioned and ornamental style latches available.

Bolts – Lock bolts are the mechanism which enters the strike to engage the lock.

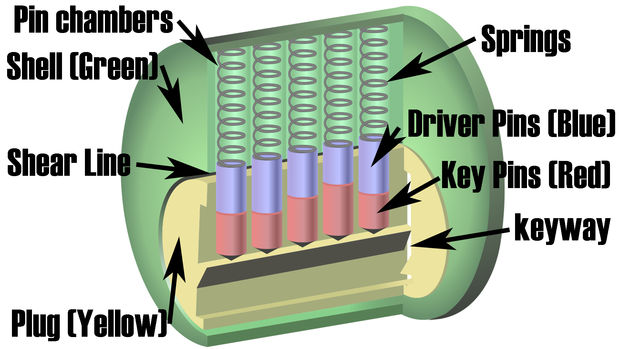

Lock Cylinder – WHen referring to a lock’s ‘cylinder’, what is being described is the component in which the key slides into where the magic happens to engage the lock bolt or latch. Most lock cylinder’s have a ‘pin tumbler’ and a ‘plug’ inside. The plug needs to rotate to operate the cam then- lockbolt but the plug cannot rotate until the proper configuration of stacked pins are resting at just the right location. These stacked pins consist of spring loaded ‘driver’ pins with ‘key’ pins below them. The joint between the two pins, when aligned perfectly straight by way of the correct key, will be on the same plane (shear point) as the joint between the cylindrical plug and the joints housing, allowing the keyholder to turn the plug, engage the ‘cam’, which operates the lock bolt in and out of the strike. It is very common for a cylinder to be manufactured so it can be unscrewed by a locksmith and rekeyed with dismantling the entire boltwork hardware.

Stop – A door stop is anything used to keep a door from swinging closed or most commonly, from swinging past the door jamb in the opposite direction, ripping out the hinges. Door stops are made of various shapes and sizes and can me mounted to the wall, base, or floor when meant to keep a door open. They also exist as the vertical continuous jamb-centered trim protruding enough to catch the door, at both sides and top of the door frame. The secondary function of the door jamb is to seal the perimeter of the door reducing air flow and increasing privacy.

Hinge

4 configurations:

-full mortise

-half mortise

-full surface

-half surface.

Typically 1-1/2 pairs per 7′-6″ of door height and are installed right or left handed (though often interchangeable with a simple configuration flip). Placed 13″ maximum from floor, then spaced equidistance with an 11-3/4″ max distance from top of door. Come in plain bearing (low frequency use doors, interior, residential), Standard Weight Ball Bearing (average frequency use: Corridors, etc, residential/light commercial), Heavy Weight Ball Bearing (high use frequency: entrances, toilet rooms, heavy commercial and industrial).

Most hollowcore doors +/- 1-3/8″ thick are coupled with two 3-1/2″ x 3-1/2″. Solid 1-3/8″ doors are typically coupled with three 3-1/2″ x 3-1/2″ hinges. For solid doors thicker than 1-3/8″, 4″ x 4″ hinges or larger are commonly used.

Ball Bearing – Heavy Doors, lubricated permanently

Continuous/Piano – Cabinets, chests, heavy doors. Distributes weight evenly

Double Action Spring – Lightweight doors, dining/kitchen doors

Flush – Cabinet doors, concealed hinge

Knuckle – Decorative doors, loose joint feature, knuckle only shows when door closed.

Ornamental/Case – Decorative look, furniture, cabinets.

Residential/Butt – Exterior/interior, lightweight doors, removable pin option, heavy gauge screws.

Surface – Bifold doors, closet doors, shutters, no mortise required.

Pivot – ALlow door to open in both directions

Closer – Commonly used in medium to high-traffic areas, and in commercial construction. Closers are chosen through a number of considerations: available mounting locations, economy, size/weight of the door, doot location within room, backswing requirements, door use frequency. Also local building codes and ADA standards (interior doors 5lb force max, exterior doors absolute minimum possible, closing speed 5 seconds max) can influence type and location of closers. Performance standards have been established which break door closers into 3 grades: Grade 1 (2,000,000 cycles at 60% efficiency), Grade 2 (1,000,000 at 60% efficiency), Grade 3 (500,000 cycles at 50% efficiency). There are 4 primary types of closers utilized as explained below:

Overhead Door Closer – Most widely used type , especially in commercial construction. Typically installed on interior office doors, glass entry doors, etc.

‘Regular Arm’ Closerrs are found on the exterior of the door with two arms, one attached to the frame and one the door with a spring loaded box.

‘Top Jamb’ Door CLosers are fairly similar to Regular Arm closers only the spring loaded box is mounted on the face of the door frame. These are frequently seen installed on aluminum or glass storefront/entry doors as they have thin top rails.

A ‘Parallel Arm’ closer utilizes arms that rest on top of the door when closed, and a spring loaded box mounted to the face of the inside of the door. They are popular due to the concealed and vandal-proof nature of the arms. They are also considered more aesthetically pleasing but typically have less power than other closer types.

Concealed Closer – Fits into the recesses of the door frame when closed and can be hydraulic or spring loaded, popular with lighter duty interior doors.

Surface Mounted Closer – SMall, fitted to door frame with a bar at back of door, typically cost effective.

Floor Spring Closer – Most commonly seen on glass storefront doors, concealed & mounted on the floor. A bar inside the closer fits into the underside of the door. Aesthetically appealing, higher end look.

Panic Hardware – A device which operates and releases a spring loaded bar and it’s lockbolt from it’s strike in an emergency situation, on a door which opens to the outside. It is commonly horizontal and near waist level for quick unlocking of a door for emergency exit. Panic hardware may be tied to the buildings alarm system, which is triggered when an emergency only panic hardware equipped door is opened. ALso panic hardware may be electrified to perform certain functions automatically (latch retraction, lever trim, delayed egress, switches, etc). Most building codes now require panic hardware as a means of swift egress on exterior doors, corridors, vestibules, etc for groups of people in case of an emergnecy. Any doors encountered by occupants (on the way to the exterior) after the first egress panic bar, will typically also require panic bars. Code typically does not allow any other locking mechanisms on a door which will have panic hardware. ‘Dogging’ a panic device consists of locking the device (with hex-key or key cylinder) in retraction to alleviate wear on the unit while allowing for a push/pull operation mode (not available for fire doors due to maintaining rating). Typically mounted 34-48″ above the threshold. Most commonly available finishes are architectural plated steel, stainless steel, powder-coated. There are 3 primary styles of panic bars:

-Touch pad – most commonly specified.

-Crossbar – often stile mounted if sufficient width exists, utilized in low profile glass doors, or when old-fashioned look is desired, often little room for electrical components

-Recessed – lower profile where the projection of the push is minimal, often used in hollow metal doors.

There are 4 types of panic bars available:

-Rim – simplest configuration & maintenance, surface mounted, latch projecting from device not door, can be used on double doors with a removable mullion

-Mortise – mortise lock body in the door, with the panic hardware placed on the face of the door controlling the mortise lock. Less common due to door prep complexity,

-Vertical Rod / Cable – primarily used on double doors, can eliminate need for mullion, surface mounted or concealed option, rod and lockbolt goes up to top of door frame strike, option of rod and lockbolt to threshold strike is available also

-Multi-Point – Combines vertical rod and RIM device for 2 or 3 point latching.

Push & Pull Bars & Plates

Push and pull bars and plates are typically vertical and flush mounted, meant for push and/or pulling a door in non-emergency applications. Also push plates exist which are simply flat sheets of metal or plastic which cover the wearing surface of a doors manual push open location. Typically mounted +/- 42″ from floor.

Kick Plates

Kick plates are utilized at the bottom of a door at the location where a door might be rubbed or kicked open frequently by occupants. Kick plates are most commonly 6, 8, or 10″ tall and almost the full width of the door.

Door Stops and Bumpers

Door stops keep a door from closing when it is to remain open, typically made of steel with a rubber end to grasp the floor surface, commonly mounted on the face of the door ready to be hinged downward to engage with the floor via friction. Some styles exist which work in tandem with a wall mounted piece which latches together.

Door Bumpers are used as a precautionary measure for unruly swinging doors to reduce the risk of damage to the wall assembly.

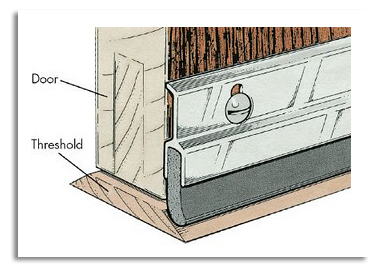

Threshold

Door thresholds are utilized to transition a door from one flooring material to another (interior) and acti as a weatherstripping barrier for moisture, air, bugs, and dirt. They are most commonly wood, extruded aluminum, vinyl steel, or a combination thereof. Choosing a weatherstripping material is often driven by matching flooring material types. There are 4 major types of door thresholds:

Vinyl – Similar to saddle type but with a strip of vinyl across the top to improve seal.

Saddle – Typically coupled with a door sweep, this is the most common type of door threshold, sealing out exterior elements. The final floor to threshold gap should be 1/8″ or less.

Panic – Used primarily for outswinging doors and commonly has a strike built or mortised in for vertical rod panic bars.

Interlocking – Commonly used in situations which in-swinging doors exposed to the elements. The threshold interlocks with a sweep or other piece attached to the bottom of the door, effectively sealing out the exterior elements.

Weatherstripping

Weatherstripping is utilized at a doors sides, top, and sometimes even bottom which is meant to lock out thermal energy, moisture, sound, and air. There are 5 primary types of weatherstripping available:

V-Strip (or friction seal) – Plastic or metal V-SHaped strip that springs open bridging gaps. Meant for sides and top of the door. Peel and stick, cut with scissors, stuck on or attached with finish nails.

Felt – Typically sold in rolls, plain or reinforced, with a metal strip. Economical but often not long lasting. Placed around perimeter of the door in the jamb, compressing when door closes. Cut with utility knife then stapled or nailed into place.

Foam – Open cell, closed cell, or EPDM rubber and a sticky back. Built to stick to the inside of the door frame

Tubular Rubber, Vinyl, or Silicone – Made of narrow vinyl or sponge tubing coupled with a wood or metal mounting strip. Acts similar to a sweep at the base of a door between the door and jamb.

Door Sweeps – Most commonly flat flaps of plastic, nylon, bristle, or vinyl coupled with a steel or aluminum piece. Unit is fastened to the bottom of the door creating a seal between the door and jamb when closed.