Glu-Laminated timber is a structural member produced by gluing (laminating) stress grade lumber with special adhesives under a controlled environment. It is common for the grain of the plies to be parallel. The main advantages over dimensional lumber are: better aesthetic appearance, various sectional shape availability, significant moisture resistance, and higher allowable stresses.

Glu-Lam timber beams can be designed to span up to 80′. A typical rule of thumb for estimating depth of Glu-Lam beams is Span/20. The width of the beam should be 1/4 to 1/3 the depth.

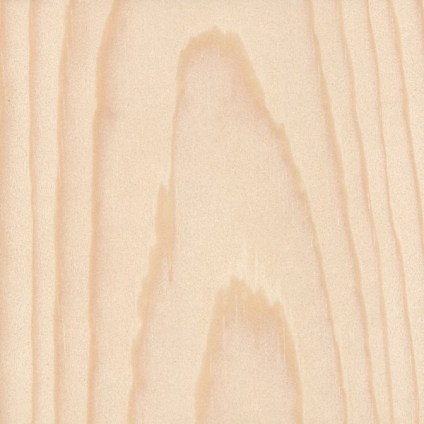

Glu-Lam timber can be utilized for beams or columns and they can also be fabricated into curved and arched shapes. A host of different species are available depending on aesthetic desire and budget. Connections are commonly made with steel fabrications, plates, bolts, and dowels. Glu-Lam is on average, 1/6 the weight of concrete and 2/3 the weight of steel and it requires significantly less energy than steel or concrete to manufacture (up to 5-6 times less in fact). The most commonly used softwood species for Glu-Lam are:

Douglas Fir

Southern Pine

Alaskan Yellow Cedar

. Hem-Fir

Spruce Pine Fir

Ponderosa Pine

Depths and lengths however are only restricted by the manufacturer’s capabilities. The 4 appearance grades from low to high are Industrial, Framing, Architectural, and Premium.

Only Architectural and Premium grades should be used where appearance is particularly important. Glu-Lam timber is typically ready to install upon delivery and the connections can be made with dowels, plate and bolt, joinery, or a combination of the 3.