After installation, it is very common for sewer mains to be tested for pressure/leakage/infiltration and also deflection. The engineer will typically specify the maximum length or section of sewer main that must be separately tested, but it is common for each run between manholes to be tested separately. Infiltration/exfiltration tests on sanitary sewers are commonly done every 900’ or structure to structure.

For pressure/leakage testing the system is filled with air and monitored on a pressure gauge typically around 4.0 psi. the amount of time for the air pressure to drop 1.0 psi is then measured against the pipe diameter and run length and compared against an engineers table for acceptance. Sanitary Sewer Air testing is commonly done between 2 manholes by plugging the pipe inside the manhole with an inflatable rubber unit which includes an air hose tap to apply air pressure into the pipe section. The common air pressure for testing is 4.0 psi unless the pipe sections under the water table in which case 0.433 psi is typically added for every vertical foot the pipe is under water.

For deflection testing it is common for the engineer to require 1 month to pass after installation of the sanitary sewer system, to allow the pipe to settle into its surroundings. The 2 most common ways to test for deflection on a sanitary sewer main is by passing a mandrel through the pipe or by a profile laser. With the mandrel test, the engineer will usually require a mandrel approximately 95% of the pipe diameter be passed between each manhole section. If the mandrel gets stuck, that section of pipe will fail and need to be repaired.

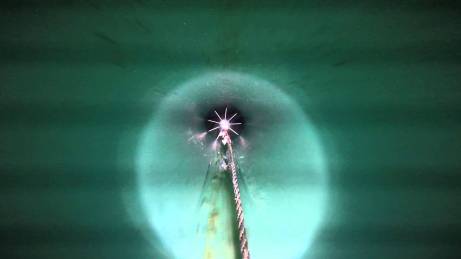

For the profile laser a robot laser system is sent through the pipe collecting accurate profile data on the pipeline. Many consider laser profiling to be more accurate and effective than the mandrel approach. Many engineers feel laser technology minimizes the chance of missing serious pipe defects sometimes experienced with other deflection testing systems. Newly placed sewer mains are often tied into the service laterals as the main is installed, making later testing under flow difficult and a health hazard. Because of this, many project engineers will allow video be done in lieu of pressure and/or deflection testing. With video the joints can be inspected, standing water in overly deflected areas can be identified, along with unwanted construction debris.

Lastly, it is not uncommon to see engineers require video of the pipelines to be taken and turned over at the completion of the project. This video is also taken by use of a robot with a mounted camera and will video the condition of the newly installed pipe in case it will ever need to be referenced at a later date. Below ground pipe video contractors will often include light pipe cleaning (water jetting) during the course of their video work.