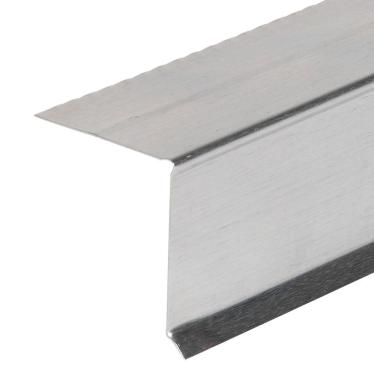

Either before or after the roofing felt is placed, drip edges (often corrosion resistant sheet metal) are installed on perimeter of roof (rakes and eaves) to resist moisture exposure to the roof edges, sheathing, or fascia boards. Drip edge is typically purchased pre-bent, installed with roofing nails, and is commonly a corrosion-resistant material like aluminum (economical) or zinc coated (galvanized) sheet steel. Ultimately the shingles should overhang from the drip edge about 1/2″.

Drip edge can be either mill finish or prefinished in white, black, or specialty colors.

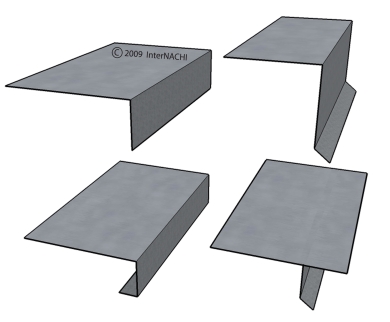

The most critical area for drip edge will be the eaves, but it is also very commonly installed on the rake of a roof. Drip edge can come in many different profiles and stock lengths usually vary from 8-12′ or more, with 10′ lengths being quite common.

Some common thicknesses typical found range from 0.011, 0.014, to 0.019″.